Mold silently costs U.S. property owners over $3 billion annually in remediation and structural repairs. While traditional building materials often fail in damp environments, advanced gypsum board systems now offer robust moisture control when installed correctly. This innovation reshapes how we protect homes and businesses from persistent water damage.

Specialized professionals bring critical expertise to these installations. They analyze airflow patterns, humidity levels, and potential water exposure points before selecting materials. Proper techniques ensure seams, joints, and fasteners maintain complete water intrusion barriers – a detail amateur installations often miss.

These systems do more than prevent unsightly stains. By creating inhospitable environments for microbial growth, they safeguard indoor air quality and structural integrity. Recent building code updates now prioritize these solutions in bathrooms, basements, and commercial kitchens where moisture accumulates.

Key Takeaways

- Proper installation maximizes material performance against water damage

- Expert assessments identify high-risk areas before problems develop

- Modern solutions meet updated construction regulations

- Quality workmanship prevents costly future repairs

- Specialized materials inhibit microbial growth effectively

Overview of Mold-Resistant Drywall Solutions

Modern construction demands materials that outsmart environmental challenges. Specialized gypsum panels now combine science and durability to combat persistent moisture issues in high-risk spaces. These innovations go beyond surface protection, addressing root causes of microbial growth through layered defense systems.

Engineering Superior Protection

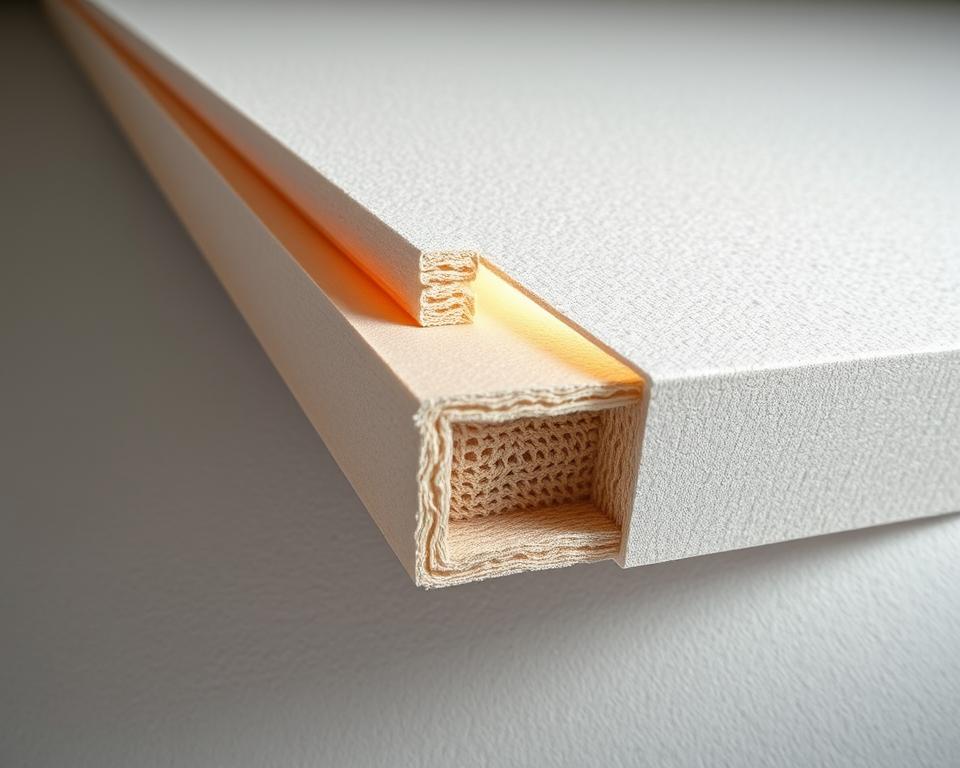

Gold Bond® XP® Gypsum Board raises the bar with its dual-layer paper technology. The front-facing PURPLE® layer repels water while the recycled gray backing blocks vapor penetration. This combination creates an inhospitable environment for spores trying to take hold.

- Tapered edges simplify alignment during installation

- Reinforced core maintains integrity in humid conditions

- Square-cut ends reduce joint cracking risks

Strategic Use in Building Design

Architects specify these panels where moisture accumulates. Common applications include:

- Bathroom walls behind tile installations

- Ceiling systems in commercial kitchens

- Basement partitions near foundation walls

“The folded paper edges aren’t just decorative – they’re critical moisture barriers,” notes a construction materials expert. Proper installation ensures these protective features work as intended across both wood and steel frameworks.

Builders appreciate the product’s adaptability. From curved soffits to angled ceilings, the panels maintain consistent performance without compromising air quality standards. Their smooth finish also reduces prep work for final surface treatments.

Technical Insights: Fire Resistance & Low-Emitting Materials

Building safety standards increasingly prioritize materials that combat dual threats: flames and fumes. Advanced construction solutions now address both fire hazards and indoor air quality through innovative engineering.

Understanding Gypsum’s Natural Fire Resistance

Gypsum contains water molecules within its crystalline structure. When exposed to flames, this chemically bound moisture vaporizes into steam. The phase change absorbs heat energy, slowing temperature rise in adjacent spaces.

This reaction gives gypsum-based panels exceptional fire resistance without added chemicals. Tests show standard ½” boards withstand direct flame exposure for over 30 minutes before core failure occurs. Builders value this inherent protection in shared walls and escape routes.

Benefits of UL Greenguard Gold Certification

Materials meeting UL’s strict emissions criteria carry the GREENGUARD Gold label. Certified products release 90% fewer volatile organic compounds than conventional alternatives. This matters in schools, hospitals, and airtight modern buildings.

The testing process subjects products to real-world conditions. Analysts measure chemical output across temperature and humidity ranges. “You can’t fake these results,” states an indoor air quality specialist. “Gold-certified boards help projects earn LEED points while protecting vulnerable populations.”

Combining natural fire resistance with low-emitting properties creates safer, healthier environments. These dual advantages make gypsum-based systems ideal for sensitive applications from neonatal units to server farms.

Benefits of Certified Mold-Resistant Drywall Contractors

Properly installed wall systems form the first line of defense against moisture-related structural damage. Specialists combine technical knowledge with advanced materials to create lasting protection where water exposure occurs most frequently.

Expert Installation Techniques

Trained professionals use specialized methods to maximize material performance. They measure humidity levels and assess airflow patterns before cutting the first panel. This proactive approach prevents gaps that could compromise moisture barriers over time.

Proper alignment ensures seamless joints between boards. Installers secure panels using corrosion-resistant fasteners spaced at precise intervals. “The difference between good and great installations shows up in year five,” remarks a Florida-based construction supervisor.

Precision with GridMarX® Guide Marks

The integrated GridMarX® system revolutionizes panel placement. Printed markers eliminate guesswork by showing exact cutting lines and stud locations. This innovation delivers three key advantages:

| Traditional Methods | GridMarX® System |

|---|---|

| Chalk line snapping | Pre-printed guides |

| Manual measurements | Visual alignment cues |

| 15% material waste | 8% material waste |

Contractors complete projects 25% faster using these guide marks while maintaining accuracy. The system works with standard tools, requiring no special training. Proper scoring techniques preserve the board’s protective layers during customization.

This combination of experience and innovation helps buildings withstand humid environments effectively. Regular inspections after installation ensure long-term performance against moisture intrusion.

Installation Best Practices and Tips

Proper panel installation techniques determine how well moisture barriers perform over time. Attention to detail during placement ensures structural resilience and continuous protection against environmental threats. These methods combine precise measurements with specialized material handling.

Step-by-Step Application Process

Begin by inspecting panels for undamaged square-cut ends. Position boards with tapered edges facing inward to create recessed joint spaces. Secure panels using corrosion-resistant screws spaced 12-16 inches apart.

Maintain ⅛-inch gaps between boards and adjacent surfaces for expansion. Support ceiling installations with temporary braces until adhesive sets. Proper alignment prevents stress points that compromise protective paper layers.

Edge Reinforcement and Joint Finishing

Tapered edges form V-shaped channels ideal for embedding joint compound. Folded face paper around long edges shields the core from humidity exposure. This dual-layer protection enhances durability in high-moisture areas.

| Traditional Edge Prep | Modern Reinforcement |

|---|---|

| Manual sanding | Factory-tapered edges |

| Single-layer compound | Fiberglass mesh backing |

| 3-day curing time | 24-hour ready-to-paint |

Apply joint tape before smoothing compound into recessed spaces. Skilled technicians feather edges to create seamless transitions between panels. Proper curing prevents cracks that could expose vulnerable core materials.

Moisture Control and Mold Mitigation Strategies

Innovative building materials now combat moisture issues at their source. Advanced systems use SPORGARD® technology to create hostile environments for microbial growth. These solutions score highest in ASTM D3273 and G21 tests, proving their effectiveness against persistent threats.

Effective strategies focus on two fronts:

- Blocking water infiltration through tight seals

- Maintaining humidity below 60% with proper ventilation

Materials with less than 5% water absorption (per ASTM C473) outperform standard options. Their dense cores repel moisture while remaining dimensionally stable. This prevents warping and gaps that let mold take hold.

| Traditional Materials | Advanced Solutions |

|---|---|

| 12% water absorption | 4.7% absorption |

| Visible expansion in humidity | 0.03% size change |

| Annual inspections needed | 5-year performance warranties |

“The right materials work like vaccines for buildings,” explains a building scientist. SPORGARD®-enhanced boards stop mold mildew before colonies form. Their chemical barriers remain active even when surfaces get damp.

Proactive measures extend beyond material selection. Install vapor barriers behind panels in high-risk areas. Use dehumidifiers in basements and mechanical rooms. Monitor humidity levels with wireless sensors for real-time alerts.

These layered approaches protect structures from hidden damage. By addressing moisture and mold mildew simultaneously, buildings maintain healthier interiors for decades.

Exploring Wall and Ceiling Applications

From bathrooms to outdoor soffits, modern materials protect structures where water threatens integrity. These systems adapt to various surfaces while maintaining consistent moisture barriers. Their versatility addresses both visible spaces and hidden structural components.

Tile Backer Applications in Moisture-Prone Areas

Specialized panels excel behind tile installations where limited water exposure occurs. Ideal locations include:

- Bathroom walls near sinks and toilets

- Shower surrounds above waterproof membranes

- Laundry room backsplashes

Proper selection depends on moisture levels. High-humidity zones require tighter seams and enhanced sealing. A recent study showed panels with integrated water barriers reduce repair costs by 40% in these applications.

| Traditional Tile Backers | Advanced Solutions |

|---|---|

| Requires separate vapor barrier | Built-in moisture protection |

| Prone to edge swelling | Tapered edges prevent water pooling |

| 6-month warranty | 3-year performance guarantee |

Exterior Soffit Considerations

Approved panels withstand outdoor conditions when installed under covered eaves. Key requirements include:

- Continuous ventilation behind the material

- UV-resistant finish coatings

- Expansion gaps for temperature changes

“Outdoor installations demand precision,” notes a Chicago-based builder. Aluminum trim helps seal edges against wind-driven rain while allowing airflow. Regular inspections ensure long-term durability against seasonal weather shifts.

These applications demonstrate how modern systems protect structures from floor to roof line. Proper material selection and installation create seamless defenses against moisture intrusion.

Certification Standards and Quality Assurance

Building materials face rigorous scrutiny before earning trusted certifications. Third-party validation ensures products perform as advertised under real-world conditions. These standards protect both structures and occupants through scientific testing protocols.

ASTM Testing for Mold and Moisture Resistance

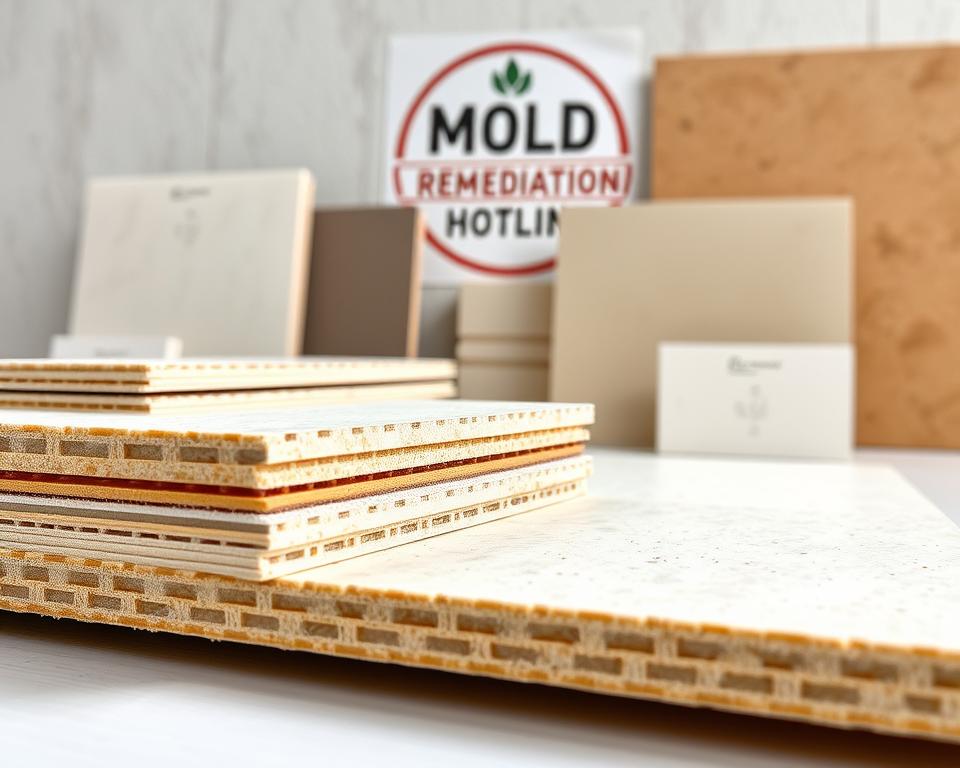

ASTM International sets the benchmark for material evaluations. Their tests simulate years of moisture exposure in controlled labs. Panels undergo:

- 28-day mold spore exposure trials

- Water absorption measurements

- Dimensional stability checks

Products passing these tests show less than 5% size change in humid conditions. This prevents gaps where moisture could penetrate wall systems.

| Standard | Purpose | Key Metric |

|---|---|---|

| ASTM D3273 | Mold growth resistance | 0% surface growth |

| ASTM C473 | Water absorption | ≤4.7% weight gain |

| UL 263 | Fire endurance | 1-hour rating |

California’s Specification 01350 goes beyond basic requirements. It measures chemical emissions over 14 days to ensure low-VOC performance. Products meeting this standard contribute to LEED-certified projects and healthier schools.

The GREENGUARD Gold Certification represents the highest air quality standard. Certified materials emit 90% fewer chemicals than conventional alternatives. This dual focus on safety and air purity makes these solutions ideal for hospitals and daycare centers.

Innovations in Gypsum Board Materials

Material science breakthroughs transform ordinary wall panels into multi-functional shields. Modern gypsum core formulations now combat moisture, flames, and microbial growth simultaneously. These advancements address critical needs in kitchens, bathrooms, and commercial spaces where multiple threats converge.

Enhanced gypsum board products use mineral additives that repel water while inhibiting mold mildew. The Gold Bond® XP® Fire-Shield® series demonstrates this dual-purpose design. Available thicknesses include:

| Product | Thickness | Fire Rating |

|---|---|---|

| Type X | 5/8″ | 1 hour |

| Type C | 1/2″ | 2 hours |

| Type C | 5/8″ | 3 hours |

Manufacturers achieve these results through layered protection systems. A dense gypsum core resists water absorption, while surface treatments block mold mildew spores. Fire-resistant additives expand when heated, creating insulating barriers.

Installers benefit from improved edge designs that simplify alignment. Reinforced paper layers prevent fraying during cutting. “The new tapered edges reduce joint compound use by 30%,” reports a Chicago construction manager. These features help projects meet strict building codes faster.

Ongoing research focuses on eco-friendly formulations. Some boards now incorporate recycled materials without sacrificing performance. These innovations help structures stay durable in humid climates while reducing environmental impact.

Conclusion

Modern construction projects demand smart solutions for moisture control and indoor air quality. Advanced board systems address these needs through layered protection against water damage and microbial growth. Their fire resistance and low chemical emissions make them ideal for kitchens, bathrooms, and healthcare facilities.

Proper installation maximizes performance in high-humidity areas. Features like folded paper edges and alignment guides ensure tight seals between panels. These details matter most in walls and ceilings where moisture often collects unseen.

Material innovations now combine durability with environmental responsibility. GREENGUARD Gold-certified products help maintain healthy interiors while meeting strict building codes. Their dense cores resist warping, even in spaces prone to dampness.

Choosing the right resources for your project prevents costly repairs down the line. Professionals with experience in these specialized applications deliver lasting results. Their work protects property values and occupant well-being through science-backed construction methods.